Rosswag Engineering Aktuell

Unsere aktuellen Beiträge aus den Rubriken News, Materials Monday, Veranstaltungen und Publikationen:

ERBE F&E Projekte

Mehr

WUe-FluB F&E Projekt

Mehr

AluScal F&E Projekt

Mehr

OptiAdd F&E Projekt

Mehr

Cooperation with VDM Metals for Alloy 699 XA

Mehr

Circular Economy at Rosswag

Mehr

IPA Anwenderforum Additive Produktionstechnologie Berlin

Mehr

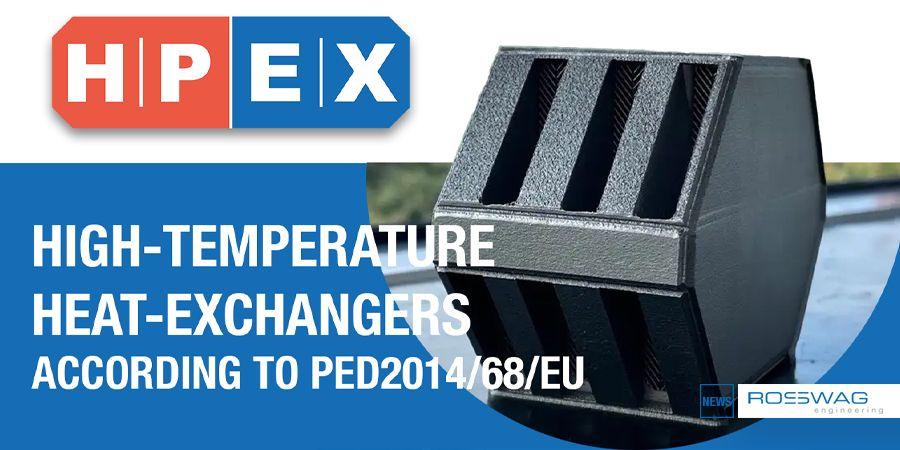

High-temperature Pressure Equipment with 316L

Mehr

Silver Sponsoring of KARaceIng with Aheadd CP1 parts

Mehr

New Materials - New Applications

Mehr

IPA Anwenderforum Additive Produktionstechnologie

Mehr

AM Forum Berlin Insights

Mehr

Material Qualification misconceptions

Mehr

Reflection Insights 8th AM Forum in Berlin 2024

Mehr

Nickel-based Superalloys

Mehr

Meet us at the 8th AM Forum in Berlin

Mehr

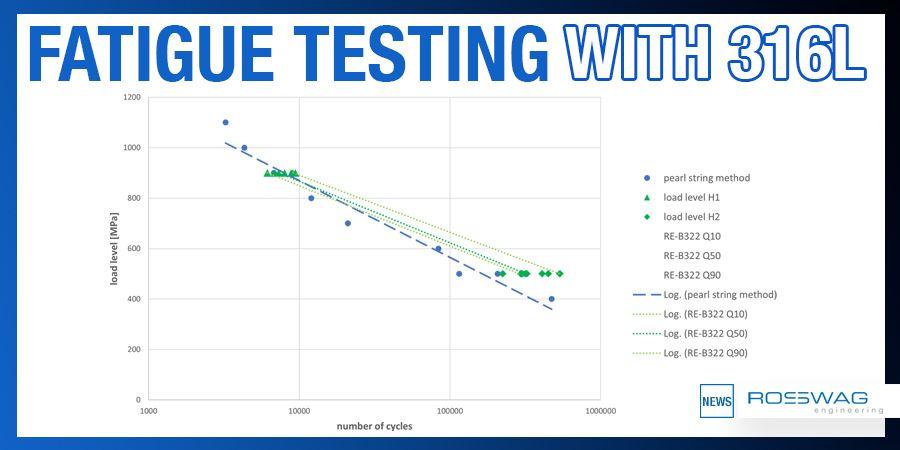

316L Fatigue Testing Results

Mehr

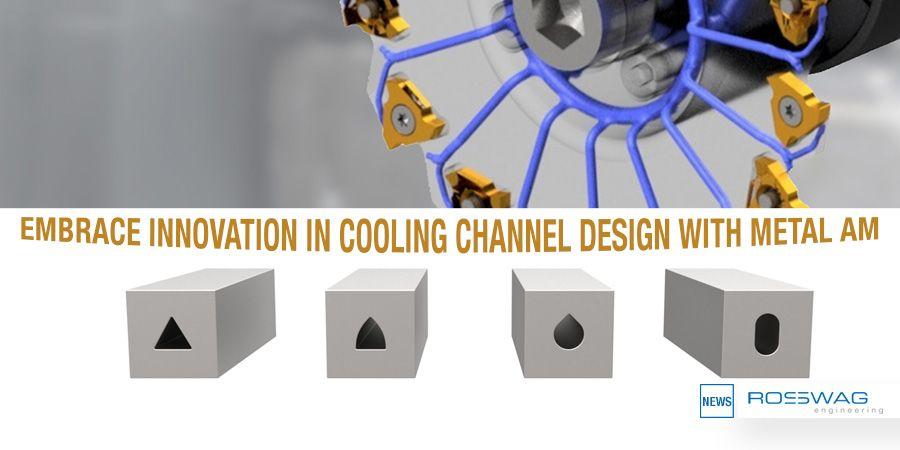

Embrace Innovation in Cooling Channel Design with Metal AM!

Mehr

Certified AM Pressure Equipment

Mehr

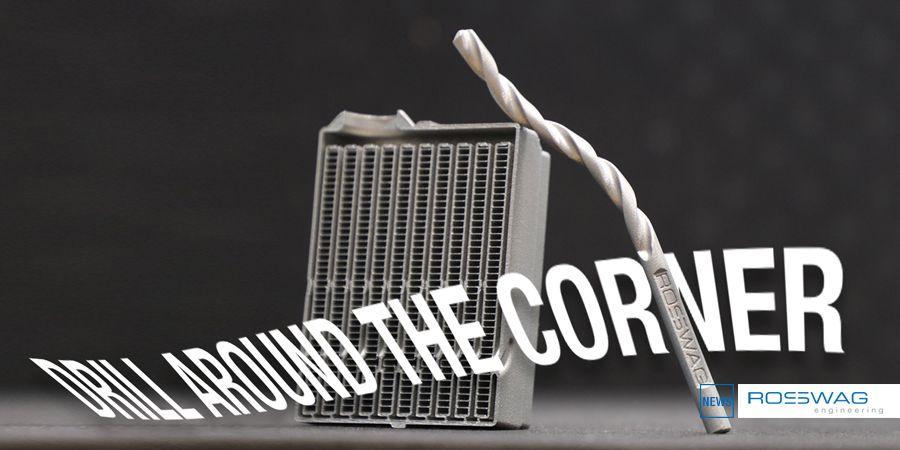

Drill around the corner

Mehr